Wide Cracks and Joints in Flexible and Composite Pavements: State DOT Maintenance Practices (2025)

Chapter: 4 Case Examples

CHAPTER 4

Case Examples

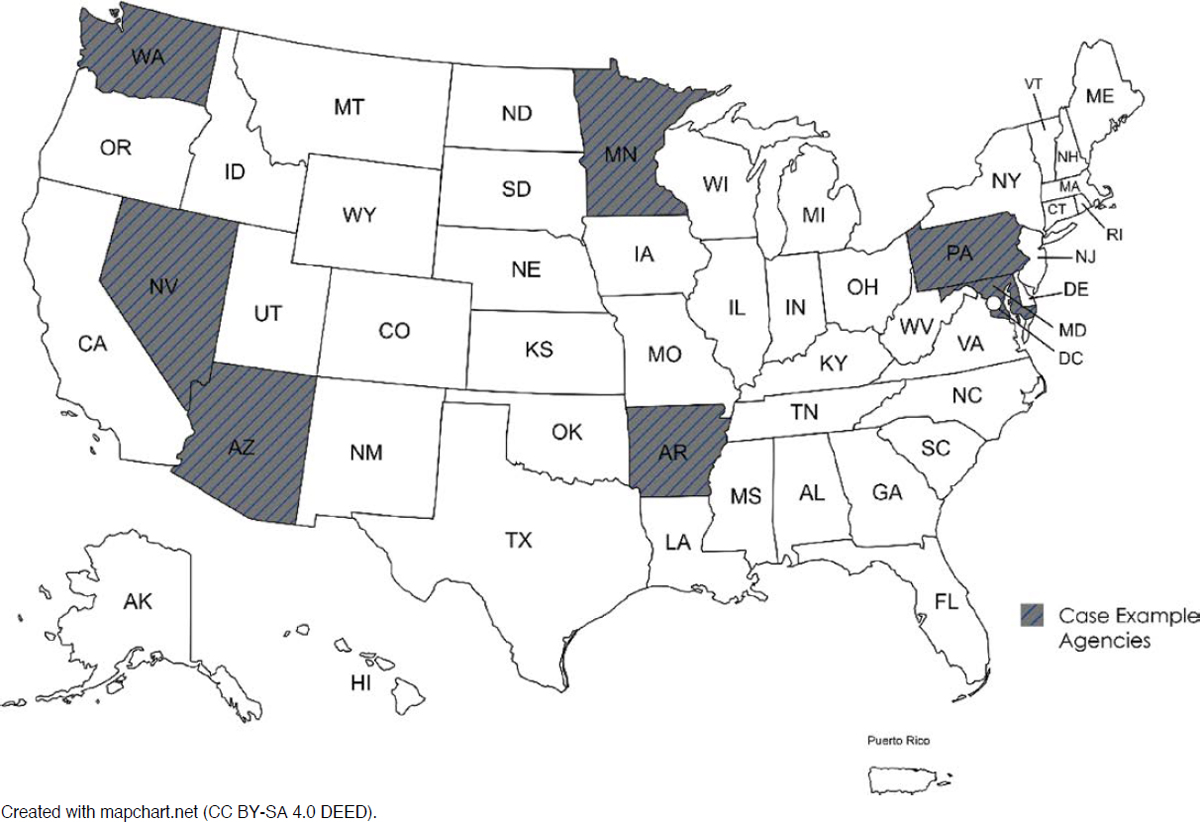

The case examples in this chapter summarize discussions with seven state DOTs participating in the state of the practice survey. These seven DOTs represent a range of environments, regions, and experiences with wide crack repair materials and procedures. Four of the seven DOTs were introduced to the use of mastics in particular for wide crack and joint maintenance in the past 6 years, while two of the seven have over 10 years of experience with mastics. Case examples also highlight a range of available DOT guidance, both formal and informal.

Case examples are provided for the following DOTs, also shown in Figure 22:

- Arizona Department of Transportation (ADOT).

- Arkansas Department of Transportation (ARDOT).

- Maryland Department of Transportation State Highway Administration (MDSHA).

- Minnesota Department of Transportation (MnDOT).

- Nevada Department of Transportation (NDOT).

- Pennsylvania Department of Transportation (PennDOT).

- Washington State Department of Transportation (WSDOT).

The questions used to initiate the conversations with each of the case example DOTs are found in Appendix C.

Arizona Department of Transportation

Geographically, Arizona spans a range of environmental conditions, from the low altitudes and desert-like conditions in the south and southwest of the state to the central part of the state with varying elevations and temperature ranges, to the northern and northeastern portion of the state, characterized by elevations between 5,000 and 8,000 feet above sea level. The temperature ranges associated with these different regions can be extreme, and on asphalt pavements contribute to the development of surface cracking. ADOT has maintained asphalt pavements with crack sealing for decades. About 9 or 10 years ago, mastics were introduced into the Arizona market as a demonstration project constructed at a material supplier’s own expense. Transverse thermal cracks 3 to 5 inches wide on US 89 were sealed with mastic by a vendor and ADOT was satisfied with the performance of the mastic crack treatments. ADOT districts became interested in using the product to maintain wide cracks, and that was facilitated by the presence in Arizona of a mastic material and equipment manufacturer. Each district worked with the material supplier to become more familiar with mastics and the DOT’s mastic specification (ADOT 2021) was developed based on the knowledge gleaned from that experimentation.

Prior to using mastic, the typical practice for wide crack maintenance was to sawcut and remove a narrow trench over the crack and then fill the trench with hot mix asphalt. ADOT reported that

while this sealed the crack, it also created two cracks (the trench joints) that could widen. When mastics were first used, they were often applied by hand with a range of surface preparation techniques, and as a result, some applications peeled up quickly because the mastic was not well bonded to the pavement. At present, techniques have been refined and mastics are successfully used throughout Arizona.

Practice

Pavement maintenance is carried out through ADOT’s Transportation Systems Management and Operations Division. Each year districts provide a list of routes they want to crack seal. The pavement management group reviews the list and evaluates the pavement condition using videologs and condition data to determine if each pavement will receive crack sealing, slurry sealing, micro surface, or chip seal. ADOT has stored specifications for two approaches to crack sealing. Item 4040305 (ADOT 2018), Seal Cracks (Polymer Modified Asphalt), is for a material that complies with ASTM D5078, a hot-applied crack filler. Item 4040302 (ADOT 2021), Wide Crack and Joint Repair Using Hot Applied Mastic, is similar to ASTM D8260. Both specifications are identified as “stored” specifications; each is customized for a given project based on the type of sealant appropriate for a specific project. That type is determined by the temperature ranges

to which the material will be subjected, as the material manufacturers for both crack sealers and mastics have developed different material formulations based on typical temperatures. This is especially important in Arizona, where the districts have pavements exposed to a range of temperatures.

Crack sealing materials (Item 4040305) are specified for cracks ¼-inch wide or wider; cracks between ¼- and ½-inch wide are routed before sealing, but cracks greater than ½-inch wide are only cleaned and sealed. This contrasts with the specification for mastic materials (Item 4040302), which is called out for cracks 1-½ inches wide or wider. Neither specification includes a crack width that is too great to be sealed or repaired with a mastic.

Preparation prior to mastic application consists of cleaning with compressed air. Mastics are placed with an appropriate mastic applicator following the material manufacturer’s instructions. Payment for wide crack and joint repair with mastics is measured by the pound.

While the specification for mastics is only 3 years old, ADOT makes widespread use of this maintenance tool. As specified, mastics are an engineered product and ADOT’s maintenance crews are familiar with how to apply the product successfully. ADOT’s typical application for mastics is on pavements that are nearing the end of their life. In addition to placing mastics over wide cracks and patches, mastics are also applied over wheelpath cracking (fatigue cracking). This is considered a stopgap repair to hold together pavements with rutting, cracking, wide cracks, and patching while a rehabilitation project is planned. ADOT does not place any limit on traffic levels, functional classification, or pavement conditions when using mastics.

Most crack sealing and mastic applications are carried out by ADOT maintenance crews. However, the mastic melter/applicator is rented from the material supplier. This relieves the DOT of the responsibility for maintaining equipment in operating condition and has the added benefit of providing access to the most recent advancements in equipment technology.

Innovations

Several processes have evolved since ADOT began using mastics. As noted previously, the stored specification for mastics is intended to produce a material that will work well in the specific environment in which it is applied. Surface preparation used both compressed air and hot, compressed air lances to ensure cracks are clean and dry prior to material application. Many applications are now carried out using specialized drag boxes, which keep the application very consistent and provide a better bond between the material and the pavement.

Performance

Mastic performance is variable and depends in part on the condition of the road and the location in which it is being used. Where snowplows are used, the treatment life may be no more than 2 or 3 years, while in warmer locations it can be 2 to 5 years. Mass patches may last as little as several months and be applied several times in the same year when placed on roads in failing condition.

While ADOT has not carried out formal cost-effectiveness studies, comparing mastic use for wide crack maintenance with the alternative, cut and patch with hot mix asphalt (HMA), mastic placement requires minimal traffic control and is simpler, faster, and less expensive. ADOT believes it may last as long as the alternative patch repair, making mastics a cost-effective wide crack repair strategy.

Challenges Identified by ADOT

The use of mastics is a district-driven decision. As such, there is variation in the practices associated with mastic use. Some of the areas where practices are being improved:

- Timing—The districts now strive to apply sealant and mastics from March to May, while the cracks are still open instead of in the summer when they are tighter.

- Past practice—Crews that are familiar with blade-laid patching and crack sealing/filling are encouraged to adopt the use of mastics for appropriate repairs.

Arkansas Department of Transportation

Arkansas’ climate is classified as humid sub-tropical, and is characterized by hot summers, mild winters, and average annual rainfall ranges between 40 and almost 60 inches. The northern half of the state experiences slightly drier and milder temperatures than the southern half.

Asphalt pavements in Arkansas that crack are sealed using conventional crack sealing materials. The widest cracks are reflective cracks typically found in asphalt overlays of concrete pavements. Crack sealing is a common maintenance strategy when the cracks are up to 1-inch wide, and wider cracks are repaired with cold or hot mix patches. In some instances, geosynthetics are used to help delay/reduce the reflective cracking. Arkansas is moving toward proactive pavement preservation, with the goal of using thinner preservation treatments to delay having to perform a 2-inch mill with a 2-inch overlay.

Practice

Crack sealing is an in-house maintenance operation using polymer-modified sealing materials conforming to ASTM D6690 (sealing materials) or ASTM D5078 (filler materials). Crack preparation consists of blowing out the crack with compressed air. Each district has crack-sealing equipment and an annual supply contract that provides the sealant materials. Crack sealing is most often a standalone activity performed during cooler months by maintenance crews. The district maintenance engineer determines which routes need to be crack-sealed, fog-sealed, or chip-sealed. The asset management section helps by reviewing automated DCV images to identify the best maintenance or preservation strategy. Of ARDOT’s 10 districts, six have active crack-sealing programs. Table 3, from the Arkansas Department of Transportation Preventive

Table 3. Asphalt pavement treatment categories (ARDOT 2018).

| Pavement condition | Crack filling or sealing | Patching | Milling and leveling | Seal treatments2 | Overlays and recycling | |||

|---|---|---|---|---|---|---|---|---|

| ≤ 1 inch | ≤ 2 inches | Category I | Category II | Category III | ||||

| Good | X | X | X | X | ||||

| Fair | X | X | X | X1 | X3 | X | X | X |

| Poor | X | X | X3 | X | X | |||

1 Milling and leveling ≤ 2 inches may be used on a pavement in Fair condition if a 2-inch mill and inlay of the main lanes is more economical than a 2-inch overlay of the main lanes and shoulders.

2 Category I: Rejuvenation, Fog Seal. Category II: Chip Seal, Scrub Seal, Slurry Seal, Sand Seal, Double/Triple Chip Seal, Sandwich Seal. Category III: Cape Seal, Open Graded Friction Course, Micro Surfacing, Ultra-Thin Bonded Wearing Course, Thin Overlay ≤ 1 inch.

3 Category I Seal Treatments may be used on shoulders in conjunction with a Category II Seal Treatment for the travel lanes where the shoulder is structurally sound and ARDOT is not placing other preventive maintenance treatments on the shoulders.

Maintenance Plan (ARDOT 2018), shows how crack sealing and filling fit into Arkansas’ overall pavement treatment strategy.

ARDOT observed that the need for crack sealing as a standalone maintenance activity has changed to the point that there is no longer a need to crack seal pavements with high-density cracking. At present, surface treatments, such as scrub seals, are much more effective at preserving high-density cracked pavements. This allows crack sealing to be placed earlier in a pavement’s life cycle when crack density is lower, keeping good roads in good condition.

Performance

In ARDOT’s experience, new asphalt surfaces do not need crack sealing for 1 to 3 years after construction. Crack sealing will give an additional 4 to 6 years of performance before another treatment is required. When preservation treatments are placed on properly cracked sealed roads, the life of the preservation treatment is extended. Crack sealing is more commonly applied to higher-volume roads. Chip seals or scrub seals are a more common application on lower-volume roads.

Innovation

There have been several demonstration projects that have introduced mastic crack-sealing materials to ARDOT, most recently in 2022. These have included the use of mastics in shallow-depth potholes, on lane lines, and in wheelpath cracks. Before and after photos of the use of mastics to repair concrete spalling on I-30 in 2022 are shown in Figure 23 (a and b). Mastic repairs in wheelpath cracks under high traffic volumes deformed during summer temperatures, leading to performance issues.

Maryland Department of Transportation State Highway Administration

Maryland experiences generally moderate climatic conditions, with temperatures ranging from mild to hot in the summer and moderate to cold in select portions of the state. The eastern portion of the state is more likely to experience hot summers and cool winters, while the western

part experiences somewhat cooler summers and colder winters. The average annual rainfall in the state ranges from 35 to 45 inches.

Practice

Mastics were introduced into the state about 6 years ago by material suppliers who constructed a demonstration project for a Maryland town. DOT representatives attended the demonstration and learned what mastics could do. Working with suppliers, MDSHA developed recommendations for the types of distresses appropriately treated by mastics. The use of mastics by MDSHA has been commonplace since 2020. All crack maintenance is outsourced, and the work is completed based on information that is analyzed and shared by the MDSHA Pavement and Geotechnical Division (Pavement).

Two MDSHA publications provide specific guidance on the use of mastics. Section 510 of Standard Specifications for Construction and Materials covers sealing joints and cracks in asphalt pavements (MDSHA 2022a). Asphalt Repair Mastic is further described in Section 911.01.02 of those specifications.

Section 510 identifies crack types, their causes, and whether they are suitable for maintenance with crack sealants or mastics as shown in Table 4. Crack sealing is further specified as appropriate for cracks from ⅛- to 1-inch wide, while mastic repair is specified for “cracks of at least 1 inch in width, small potholes, dislodged reflective markers, and other vertically uneven roadway elements.”

More detailed information is contained in the MDSHA Pavement and Geotechnical Guide (MDSHA 2022b):

- Table B.1/Section 2.09.01 provides background information on mastics, including treatment advantages and disadvantages, cost information, typical life extension, and time to trafficking.

- Sections 2.08.03.05 and 2.09 provide additional information about crack sealing and mastic sealing.

- In Section 6.05.04, mastics are identified as the appropriate treatment for high-severity, non-wheelpath cracking, with or without milling, and for any asphalt concrete thickness.

Table 4. Relationship between crack type and suitability for maintenance with crack sealants or mastics (MDSHA 2022a).

| Crack type | Crack cause | |

|---|---|---|

| Suitable for maintenance with crack sealants or mastics | Transverse thermal cracks | Cracks caused by shrinkage of the asphalt concrete (AC) surface; these cracks are not caused by loadings. |

| Transverse reflective cracks | Cracks caused by cracking beneath the surface course, including cracks or joints in underlying portland cement concrete slabs. | |

| Longitudinal reflective cracks | Cracks parallel to the centerline that may be caused by shrinkage of the AC or by reflection of a crack or joint in underlying layers. | |

| Longitudinal cold joint cracks | Cracks caused by poorly constructed paving lane joints or poor joint location. | |

| Not suitable for maintenance with crack sealants or mastics | Alligator cracking | Cracks caused by fatigue failure of the AC surface under repeated loading, typically in the wheelpath. |

| Edge cracking | Cracks parallel to and usually within 1 to 2 feet of the outer edge of the pavement. | |

| Slippage cracks | Crescent-shaped cracks formed when braking or turning wheels cause a poorly bonded surface to slip or slide over the underlying layer. |

- For joint reflection cracking when the deflections at the cracks are less than 0.016 inches, mastics may be considered when the cracks are wide but exhibit minimal secondary cracking.

- Similar to Section 510 of the Standard Specifications, Section 9.01.01.01 of the Pavement and Geotechnical Guide states that “Mastic is intended to fill open cracks and joints at least one inch wide. It can also be used to fill small potholes, rumble strips, and level up bridge approaches and manholes.”

It is not MDSHA’s policy to use mastics for end-of-life repairs.

The MDSHA Pavement and Geotechnical Division (Pavement) plays a significant role in crack-sealing activities on state routes. The information used to determine the need for crack repair comes from MDSHA’s automated DCV and its processing capabilities. Cracking data are divided into structural cracks (found in the wheelpath) and functional cracks. Cracking data are then analyzed along with friction, rutting, and ride quality to determine a remaining service life (RSL) value, which in turn is used to identify the most cost-effective treatments. Crack-sealing projects are frequently identified as the most cost-effective because of their comparatively low cost. The list of proposed crack-sealing projects is sent to the districts, which use the list and other available information to put together their pavement program.

Once a district decides to do crack sealing, the Pavement group reviews the project by looking at their DCV images and verifying that crack sealing is appropriate. They will also determine the lengths of cracking eligible for crack sealing and mastic placement, typically by applying a percentage of the total cracking length to sealing and mastic placement. That information is returned to the district, which will take the sealing and mastic quantities and put them into a contract. Once estimated quantities are determined, the Pavement group’s involvement is complete, and the project is in the district’s hands.

Performance

MDSHA has yet to document the performance of its wide crack repair materials and procedures. While Section 2.09.01 of the Pavement and Geotechnical Manual (MDSHA 2022b) states that the typical life extension of a mastic treatment is 2 to 10 years, MDSHA does not yet have 10 years of experience with this treatment.

MDSHA has not conducted any studies on the cost-effectiveness of its strategy for maintaining wide cracks and joints. Mastics are expected to be cost-effective when applied to pavements exhibiting the appropriate distresses.

Innovations

Even though MDSHA has approximately 4 years of experience using mastics, guidance for their use is well-documented in multiple department resources, such as the Pavement and Geotechnical Manual (MDSHA 2022b). One practice employed by the Pavement and Geotechnical Division consists of providing a memorandum to districts that have scheduled a crack sealing and mastic repair project. The memo includes the following information for a given project:

- Quantity recommendations and locations for crack sealing and mastic repair.

- Distress types identified during a project-level evaluation.

- RSL analysis.

An example memo is found in Appendix D. The Pavement Division assembles this from DCV data and project-level evaluations. Of special note in that example memo is the series of photographs that are intended for the district to deliver to the contractor. These show the various types of pavement distresses that will be encountered and whether they are candidates for crack

sealing, mastic repair, or neither. Following completion of these projects, the Pavement Division compares post-construction quantities to estimates and determines how much life extension was achieved from the project. The quantities are also added to the pavements’ construction history.

Challenges Identified by MDSHA

As they gain experience using mastics, MDSHA identified several ways that practices for sealing wide cracks and joints can be improved. These include:

- Documenting best practices for preparation and construction.

- Identifying the materials that work best in Maryland’s environments.

- Distinguishing expected performance based on the different distresses treated with mastics.

Minnesota Department of Transportation

The northern third of Minnesota is characterized by cold winters with average temperatures in the single digits and moderate summers with average temperatures in the mid-60s. The southern third has slightly warmer winters and summers, with average lows in the teens and average highs of around 70°F. Overall, the state can be generally characterized as having cold winters and hot summers.

Asphalt pavements experiencing temperatures cycling between extremes of cold, warm, and hot are likely candidates to develop transverse thermal cracking. As those cracks widen, they become a challenge to seal using conventional crack sealant materials, such as those conforming to ASTM D6690.

MnDOT has been managing the problem of maintaining wide cracks and joints in asphalt surfaces for over 20 years. A 2001 asphalt pavement maintenance handbook (Mn LRRB 2001) identified the following techniques that could be used to repair wide cracks:

- Micro surfacing or slurry repairs.

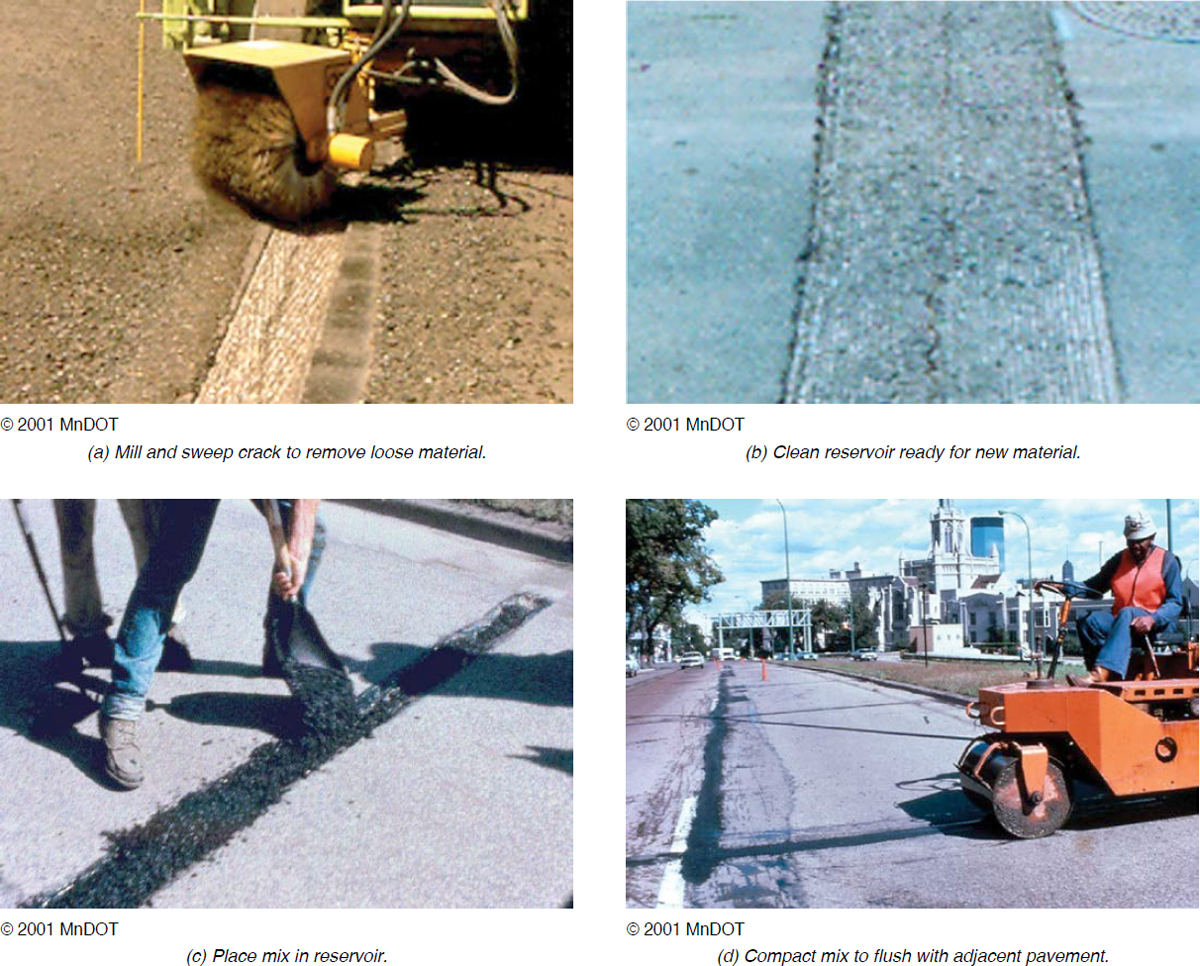

- Full-depth crack repair by milling a trench over the crack and filling it with asphalt in one or more compacted lifts (also referred to as mill-and-patch or slot paving).

The mill-and-patch technique is illustrated in Figure 24. MnDOT also included spray injection patching as a transverse crack repair method.

Since 2001, the use of mastics for the conditions previously addressed by mill-and-patch or spray injection patching techniques has grown substantially. Mastics are discussed in the MnDOT Pavement Preservation Manual (2020) as follows:

- Along with seal coats, thin asphalt overlays, and fog seals, “mastics for void filling” is identified as a pavement preservation treatment for flexible pavements.

- Mastics are described as an appropriate treatment “to level cracks that have become cupped due to erosion of the underlying base material but can also be used to fill other minor voids such as small potholes.”

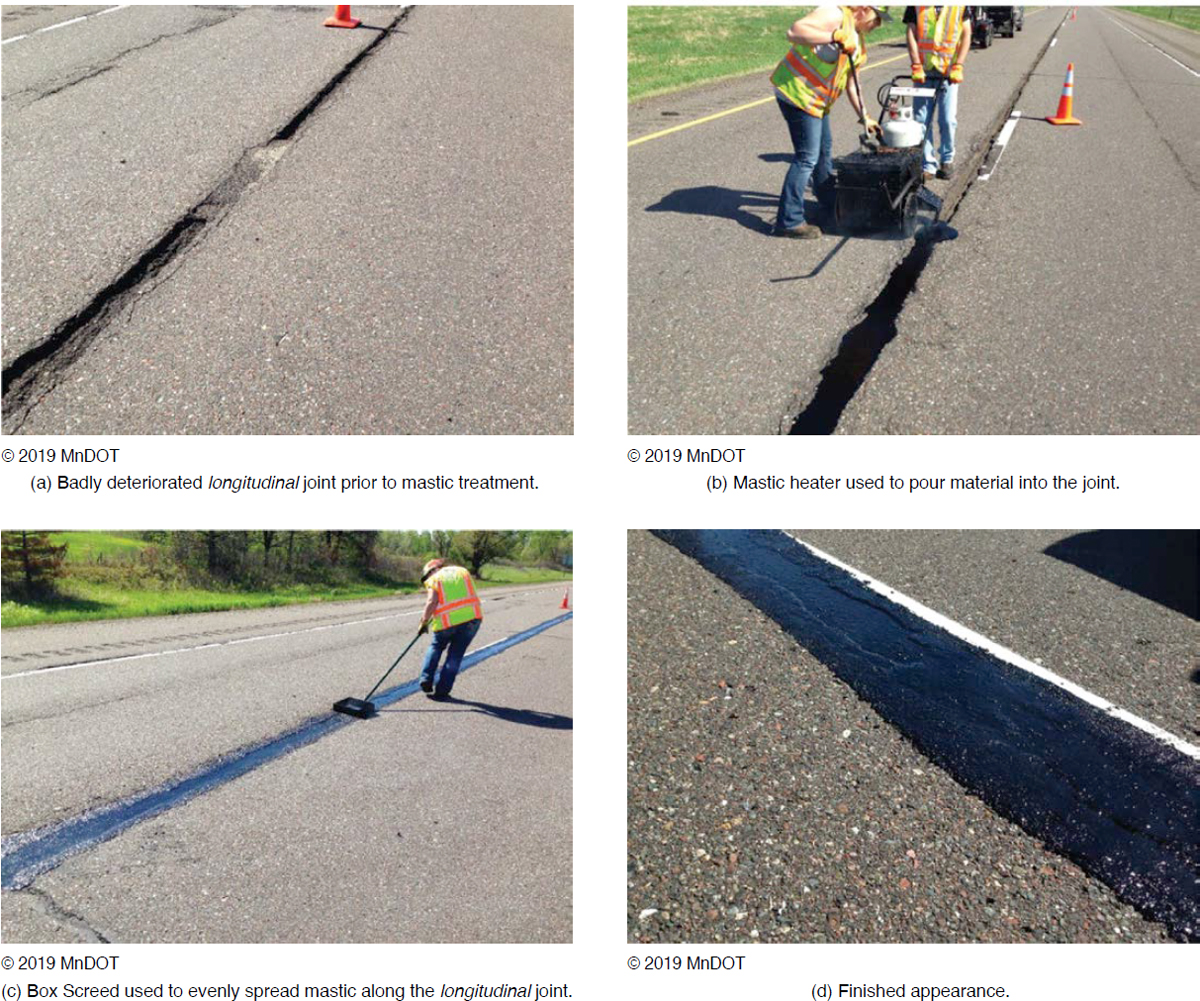

- Mastics are used to seal longitudinal joints that have medium- to high-severity deterioration. It may be combined with milling out extremely spalled areas to achieve better results.

MnDOT also uses blow patching (often referred to as spray injection patching) to seal open transverse cracks (see Figure 6 for an example of a wide longitudinal crack sealed by spray injection patching).

These different uses demonstrate that MnDOT’s use of mastics for pavement sealing is mature.

Practice

MnDOT’s districts embrace the use of mastics to maintain wide cracks and joints. Some of the districts also use mastics to patch potholes. When there is a large failure of a longitudinal joint, the treatment may either be a mastic or a mill and patch with asphalt concrete (AC). However, mastic materials cost more than other patching materials (e.g., crack sealant, AC), which limits how much is used.

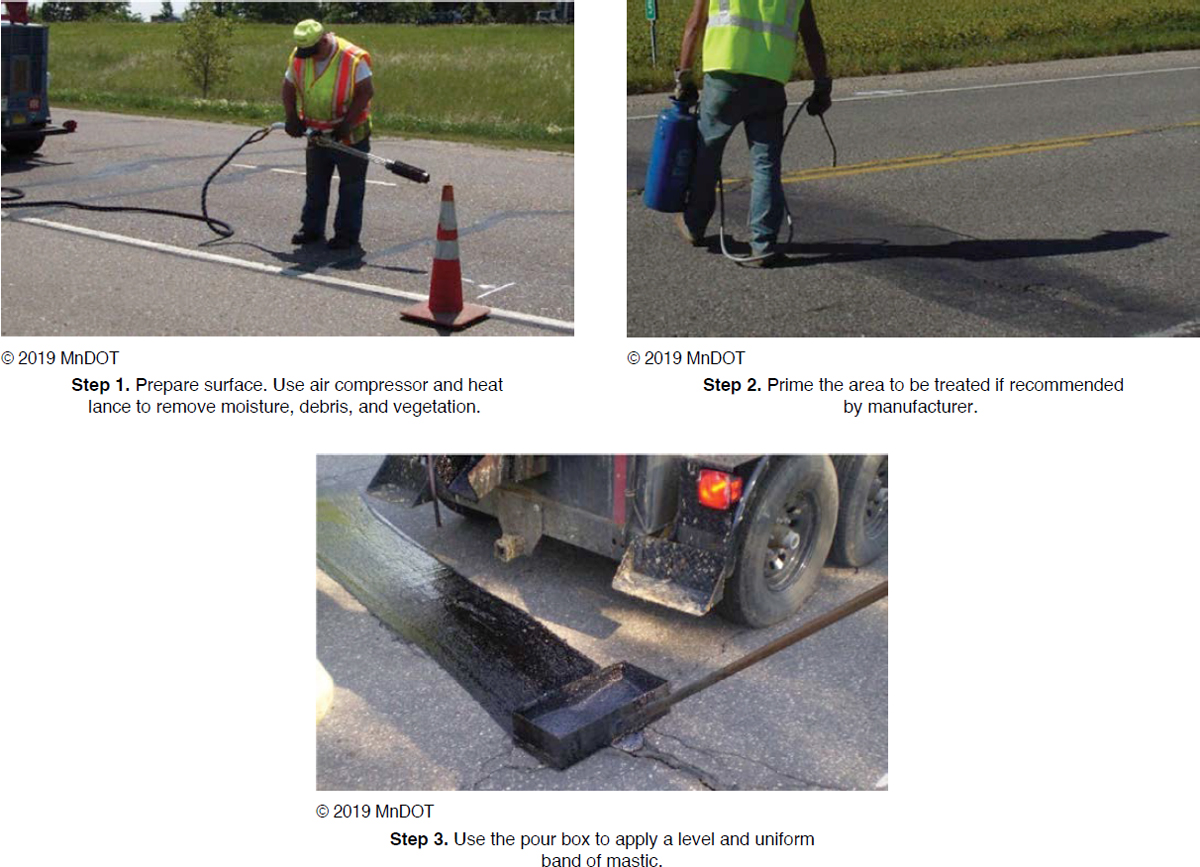

All districts either own or rent mastic applicator equipment. Districts teach their staff how to use the equipment, and material suppliers assist by providing training. Figure 25 shows the mastic application steps from the MnDOT Pavement Preservation Manual (MnDOT 2020).

Performance

With over 20 years of experience using mastic materials, MnDOT has more long-term performance data. They estimate that mastic repairs last between 2 and 8 years, depending on the age of the pavement and its distresses. Mastic repairs placed over cracks in better condition

will last longer while sealing on pavements that are raveling or carry high traffic volumes will not last as long. Figure 26 shows the steps in a mastic treatment application (MnDOT 2020).

Mastic use by MnDOT is a well-documented process that began over 20 years ago and continues to this day. Table 5 shows mastic used and costs for MnDOT’s eight districts for the past 4 years.

Experience Gained

MnDOT continues to support mastic research through its involvement with MnROAD (MnDOT’s pavement test track), the National Road Research Alliance, and its partnership with the National Center for Asphalt Technology. Experimental sections using mastic sealant have been constructed over both transverse and longitudinal cracks.

Challenges Identified by MnDOT

- The ability to complete large-area repairs with mastics is limited by the size of the heater/applicators and the time required to heat up a kettle of mastic. If there is a large sealing project the material contained in a single heater/applicator may be used up in a few hours. Multiple applicators are therefore needed to effectively and efficiently take on larger projects.

Table 5. Minnesota DOT historical mastic use and cost (courtesy of MnDOT).

| Fiscal year | Pounds of mastic used | Total cost | Cost per pound |

|---|---|---|---|

| 2021 | 2,153,985 | $3,030,067 | $1.41 |

| 2022 | 1,460,446 | $2,052,037 | $1.41 |

| 2023 | 1,777,691 | $2,477,155 | $1.39 |

| 2024 | 1,665,892 | $2,415,543 | $1.45 |

- There is a question of whether mastic-sealed pavements can be effectively milled. Should mastics be removed prior to milling? This needs to be determined.

- Maintenance crews would benefit from more workmanship training. There is limited time to work the material, and if not placed properly, it can leave a bump rather than a smooth surface.

Nevada Department of Transportation

Nevada experiences a very wide range of climatic conditions, but the state is generally categorized as dry with large temperature variations. In the western portion of the state, much of the climate is affected by the Sierra Nevada mountains. Throughout the state, the climate is also affected by differences in elevation: elevations range from less than 500 feet in the southeast to more than 13,000 feet in the north. Further, daily temperature fluctuations of 45°F are noted regularly. These climatic conditions severely stress asphalt pavements, which oxidize in dry environments with significant ultraviolet light exposure and expand and contract with diurnal and seasonal temperature cycling. As a result, thermal cracking is a common distress in Nevada’s asphalt pavements.

Before wide crack repairs with mastics were introduced in Nevada, AC crack patching was the most commonly used strategy. It worked relatively well but was expensive. Patching also introduces two joints or additional cracks that then need to be kept sealed. In addition to patching with asphalt in a mill-and-patch application, NDOT also has limited experience using a micro surface or slurry seal in a mill-and-patch application.

NDOT has used mastics formally for about 4 years and informally for several years before that. NDOT’s experience with mastics started with informal trials by districts and the sharing of results by word of mouth. NDOT then tried mastics in short applications on a range of conditions and saw positive results. Now successful applications for using mastics are shared among the districts at annual meetings and through internal maintenance training. Multiple material vendors are also engaged in making presentations about how and where to use the product which has also helped to further its adoption. NDOT acknowledges the good support provided by material vendors on the proper use of mastics through information sharing and training. However, while the use of mastics for sealing wide cracks and joints is well established, it has yet to be identified as a unique treatment in NDOT’s Maintenance Manual (NDOT 2017).

Practice

NDOT has not established a strict distinction between wide and non-wide cracks, especially at the project level. However, on pavements selected for crack sealing, it is standard practice that if most of the cracking is narrow (less than 1.5 inches), the maintenance work will consist of crack filling/sealing; while if the majority of cracks are wider than 1.5 inches, the project will receive a wide crack treatment, which most often is a mastic. Wide cracks are sealed with mastics in both a preservation application and as a stopgap treatment placed in the hope that the mastic can keep the pavement functionally serviceable until it is rehabilitated. Mastics are sometimes used as a pre-treatment prior to the application of a preservation treatment.

Different mastic types are used in the different geographic areas, which are largely based on temperature ranges but may also take traffic levels into consideration (i.e., on lower-volume roads they tend toward using mastics with softer binders). Importantly, for a given project, NDOT will also consider input from the material suppliers on the appropriate mastic type. In total, NDOT has used nearly a half dozen different products over the past few years.

Crack sealants and mastics are procured annually through an open terms contract (OTC). These contracts are developed for the districts by the Maintenance Division and identify qualified vendors, estimated quantities, and price per ton for approved materials. As an example of recent usage, the 2023-2024 OTC for mastics showed 300 tons for District 1, 900 tons for District 2, and 450 tons for District 3.

Crack repairs using mastics are most often carried out by maintenance crews using rented equipment, but may also be incorporated into an advertised contract, such as packaged with a chip seal project. Pavement preparation for mastic application consists of blowing out the crack with compressed air. They do not use a hot air lance.

Performance

NDOT does not yet have long enough experience using mastics to seal wide cracks and joints to determine how long they ultimately last. When applied appropriately, they expect to get several years of life from these treatments beyond the 2 to 3 years they have currently observed. When mastics have failed, it has typically been because of delamination (placement over a poorly prepared surface), or secondary failure due to the use of over-fatigued pavement. Because some rehabilitation projects are being delayed, NDOT is expecting to rely on the longer life of these materials in the future. When used as a stopgap treatment, they expect to get 3 to 5 years of life from mastics and expect that mastics will be reapplied rather than going to a more extensive repair.

Innovations

One of the biggest innovations was NDOT’s move to use mastics. Before this change, the primary treatment for wide cracks was partial-depth patching. This was comparatively expensive and took more time to construct.

Experience Gained

As the use of mastics has increased, NDOT has learned many lessons:

- If the substrate is not properly cleaned before applying the mastic, it is unlikely to bond well.

- Cracks also need to be properly prepared (clean and dry) before application.

- Mastic materials need to be matched to the temperature ranges at the project location.

NDOT is also continuing to collect information about the best practice regarding placement of excess sealing material on the surface (overbanding) with a mastic using different applicator shoe widths, particularly when followed shortly after by a surface treatment.

Challenges Identified by NDOT

NDOT is actively seeking solutions to improve its maintenance practices while facing staffing and funding challenges. Another challenge is the need to extend pavement life. NDOT anticipates not only trying to extend the life of mastic applications but also extending where they can be applied. To meet this challenge, NDOT would like to learn more about the following:

- What are all the conditions appropriate for mastic repairs and what are the best repair techniques?

- How soon can a preservation treatment be placed over a mastic?

- Can a mastic placed over fatigue cracking be followed by a thin surfacing and provide acceptable performance?

- Does the presence of mastics in a pavement affect the feasibility of future rehabilitation strategies, such as milling operations and future surface treatments?

- What are best practices for operations with both traditional crack filling and mastic applications? Are two separate, simultaneous operations the only option?

Pennsylvania Department of Transportation

Pennsylvania experiences a range of climatic conditions, with the northern half of the state generally exposed to colder winters than the southern half. The mountainous central part of the state also sees a colder climate. The northern portion is characterized as a warm, humid continental climate, and the southern portion as a hot, humid continental climate. The statewide average annual rainfall is 41 inches per year, but the northwestern portions of the state near Lake Erie see much more precipitation.

The combination of Pennsylvania’s climate and pavement materials has not led to the development of many AC pavements exhibiting wide transverse cracks. This is true both for higher-volume interstates and state highways as well as lower-volume roads. With many asphalt-overlaid concrete pavements, reflection cracking is a fairly common distress, and those reflection cracks can widen over time.

Over the years, PennDOT has used a variety of strategies to repair wide cracks. These have included mill and patch with warm mix asphalt repairs and micro surface overbands on deteriorated centerline joints. Mastic repairs of wide cracks were introduced by PennDOT around 2018/2019.

Practice

While some of the wide crack sealing using mastics is applied by PennDOT maintenance crews, other mastic repairs and all micro surface placements are accomplished by contract. The specific application of mastics for cracks and small patches is described in PennDOT’s Highway Foreman Manual Publication 113 Assembly Standard (maintenance guideline) for Hot Pour Mastic (HPM) (PennDOT 2024b). This is provided for reference in Appendix E. The following are some key aspects of the HPM guidelines:

- Application of mastics is intended for cracks greater than 1-inch wide. These include longitudinal cracks, transverse cracks, miscellaneous cracks, minor potholes, and other localized distresses.

- Mastic crack repairs are considered pavement preservation.

- Repairs are to be applied when the pavement temperature is above 50°F.

- Cracks or repair areas shall be thoroughly cleaned of all dirt, dust, vegetation, and/or foreign materials using 100 pounds per square inch of compressed air.

- Sealant material should extend 6 inches beyond the distress.

- When applied in thicknesses exceeding 2 inches, aggregate must be added, according to the manufacturer’s recommendations, to improve structural integrity.

- Traffic should be kept off the mastic until it is cured.

The micro surface treatment used to seal cracks (Type A) is described in PennDOT’s Specification Publication 408, Section 483-Polymer-Modified Emulsified Asphalt Paving System (Micro Surfacing) (PennDOT 2020). There are no stated usage limits in terms of pavement condition or traffic for either mastic or micro surface repairs. Usage is driven by the width of the crack. However, micro surface is typically not applied to wide transverse cracks or joints. As of May 2024, there are five mastics approved for use on asphalt pavements in PennDOT Bulletin 15, Qualified Products List for Construction (PennDOT 2024a). Two suppliers in this list also have hot pour mastics approved for use on concrete pavements.

Performance

PennDOT does not report much difference in performance between the micro surface repairs of wide cracks and the mastic repairs. The typical expected life is 3 to 5 years, but it is dependent on the overall pavement condition and the extent of deterioration at the open crack or joint. An advantage of micro surface repairs is that the laydown equipment carries more material and places that material faster. This contrasts with the mastic melter/applicators. If high production rates are needed, multiple kettles must be used on the job. Mill-and-fill repairs, on the other hand, are commonly applied to more significantly distressed wide cracks. Those repairs are a stopgap measure until a more comprehensive rehabilitation project can be constructed. Because they are applied before a complete failure, mastics are expected to last longer.

Innovations

Hot pour mastics are an innovation that was pursued by the Pennsylvania State Transportation Innovation Council’s (PennDOT STIC) Maintenance Technical Advisory Group. As noted in the 2018 STIC Annual Report:

Mastics can be used as a one-time application any time of the year for large cracks and small potholes in concrete and asphalt pavements. It combines the flexibility and adhesion of rubberized asphalt sealants with the strength and load-bearing capabilities of engineered aggregates that completely fill the repair void. The result provides a stable, flexible repair that bonds firmly with existing pavements to seal out water, return structural strength, improve ride quality and prevent further damage for years to come. (PennDOT STIC 2018)

A wealth of information about the introduction of mastics in Pennsylvania is found on the PennDOT STIC webpage (https://www.penndot.pa.gov/about-us/StateTransportationInnovationCouncil/Innovations/Pages/Hot-Pour-Mastics.aspx). Figure 27, taken from that webpage, shows the mastic application over a transverse crack in an asphalt surface (PennDOT STIC 2024).

Challenges/Opportunities Identified by PennDOT

As noted previously, one of the challenges with the use of mastics is the limited production rate of a single melter/applicator. Because of the material capacity and heating requirements

of melter/applicators, a project with a wide longitudinal crack several miles long will require multiple pieces of equipment to seal in a continuous operation.

PennDOT is interested in better understanding the cost-effectiveness of the alternatives they use for the maintenance of wide cracks. They would like to better understand the costs and benefits of mastics, mill and replace, and micro surface by having better access to treatment life data, costs, construction times, and related information.

Washington State Department of Transportation

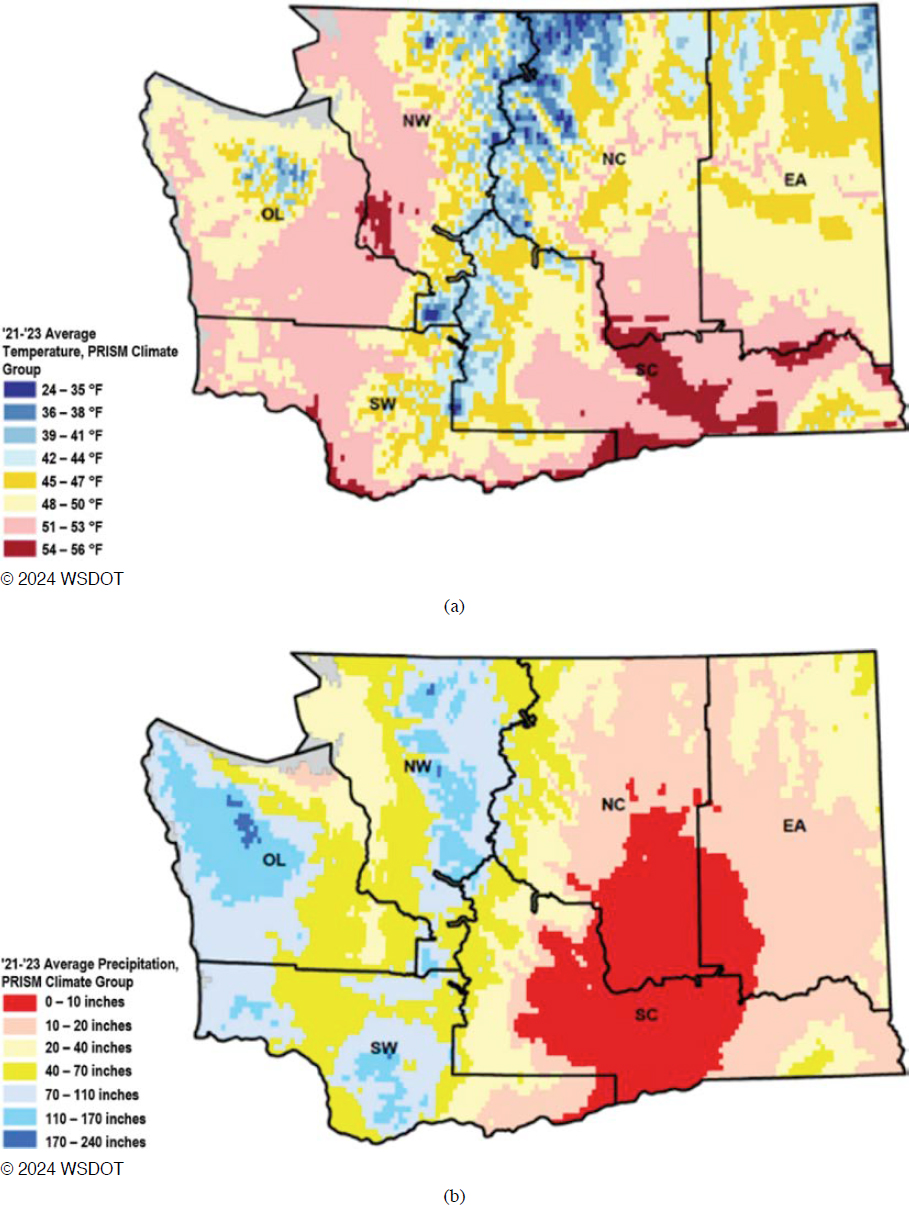

The Cascade Mountains divide Washington into distinctly different environmental zones. The western portion of the state sees a lot of rainfall but comparatively moderate temperatures while the eastern portion sees more temperature swings, with colder winters and warmer summers. The northeast corner of the state experiences very cold winters while the southern portion sees fairly high summer temperatures. Washington stands out as a state with four climatic zones. Figure 28 illustrates Washington’s average temperatures and precipitation.

The first documented use of mastics by WSDOT was in the North Central region (characterized by cold winters and warm summers). Asphalt pavements in this region developed many wide (>1 inch) transverse cracks which were repaired using a mastic material with polymers. WSDOT observed that this repair performed better than their typical practice of sealing with a rubberized crack seal and the resultant surface provided a better ride than crack sealed pavements. Several years later the pavement surface was covered with a chip seal, and that also provided good performance. Figure 29 shows examples of wide transverse and longitudinal cracks in Washington.

In 2014, as part of a larger evaluation of various maintenance and preservation treatments, a test site using a proprietary mastic was constructed on SR 155 (Anderson et al. 2018). The 8-year-old pavement surface exhibited wide and deep transverse thermal cracks which were sealed with the mastic and a chip seal was applied over the entire surface. After 38 months of performance, the surface was slightly depressed over the deep crack fillings and a thin crack was visible on the surface. Nonetheless, WSDOT viewed this as a positive outcome and the broader use of mastics as an approach to managing wide cracks developed from that experience. In 2020, WSDOT adopted a standard specification for mastic materials (9-04.2(1)C) (WSDOT 2024), identified as a product meeting the requirements of ASTM D8260, Standard Specification for Hot-Applied Asphalt Aggregate-Filled Mastic (ASTM 2020).

Practice

WSDOT has not had pavements with a lot of wide cracks in the past. Many of the asphalt pavements in the state were designed and constructed as perpetual pavements so that only surface maintenance would be needed. Two factors contributed to changing conditions, however. One is that these pavements have begun to reach the end of their structural lives, and they are developing deep, bottom-up cracking. The other is that funding for roadway preservation has declined since 2001, and pavement deterioration has accelerated.

WSDOT maintenance forces do most of the pavement preservation work in-house, including crack sealing, select chip sealing, and mastic sealing. Work is done with preservation funding and equipment is leased when necessary. Several resources are available to support the use of mastics. Tables 6 and 7 are taken from guidelines made available to maintenance personnel in WSDOT’s Highway Activity Tracking System, their Maintenance Management System (MMS).

Table 6. Excerpt from WSDOT maintenance guidelines for crack sealing, including use of mastics for cracks wider than 1 inch, and chip seal (courtesy of WSDOT).

| Description of defect | Severity | Crack seal1 | Chip seal | |||

|---|---|---|---|---|---|---|

| Rubberized | Mastic2 | Sand slurry3 | Full-width | Wheelpath | ||

| Alligator cracking | Low < 1/4” | |||||

| Moderate 1/4”-1/2” | ||||||

| High > 1/2” | ||||||

| Transverse cracking | Low < 1/4” | |||||

| Moderate 1/4”-1” | ||||||

| High > 1” | ||||||

| Longitudinal cracking | Low < 1/4” | |||||

| Moderate 1/4”-1” | ||||||

| High > 1” | ||||||

| Potholes | ||||||

| Raveling | ||||||

| Rutting4 | ||||||

| Studded tire wear5 | ||||||

| Settlement | ||||||

| Life extension, range | 3-6 years | 3-6 years | 3-6 years | 2-6 years | 2-6 years | |

| General cost | Low | Low | Low | Medium | Medium | |

Notes:

|

Shoulder repair should be dictated by the type of defect.

1 If a crack is spalling, crack seal will not be the best choice. 2 Crack seal – Mastic is a rubberized mastic material that is best used for cracks wider than 1 inch. 3 Crack seal – Sand slurry seal should only be used if there is an overlay scheduled within 1 year or less of the maintenance work. |

|

|

4 Rutting refers to when the pavement is unstable and pushing or shoving. It is best to remove rutting/shoving pavement. 5 Studded tire wear refers to the distinct wear in the wheelpaths caused by studded tires. The best techniques to deal with this distress are to fill in with a wheelpath chip seal or remove the issue. In general, the best choices will yield the longest service lives. |

|

Table 7. Excerpt from WSDOT maintenance guidelines for mill and fill patch, grader patch, thin overlay, hand patch, durapatch, and fog seal (courtesy of WSDOT).

| Description of defect | Severity | Mill and fill patch | Grader patch | Thin overlay | Hand patch | Durapatch | Fog seal |

|---|---|---|---|---|---|---|---|

| Alligator cracking | Low < 1/4” | ||||||

| Moderate 1/4”-1/2” | |||||||

| High > 1/2” | |||||||

| Transverse cracking | Low < 1/4” | ||||||

| Moderate 1/4”-1” | |||||||

| High > 1” | |||||||

| Longitudinal cracking | Low < 1/4” | ||||||

| Moderate 1/4”-1” | |||||||

| High > 1” | |||||||

| Potholes | |||||||

| Raveling | |||||||

| Rutting4 | |||||||

| Studded tire wear5 | |||||||

| Settlement | |||||||

| Life extension, range | 4+ years | < 3 years | 4+ years | < 1 year | 1 year | 1-2 years | |

| General cost | Medium | High | High | Low | Low | Low | |

Notes:

|

Shoulder repair should be dictated by the type of defect.

1 If a crack is spalling, crack seal will not be the best choice. 2 Crack seal – Mastic is a rubberized mastic material that is best used for cracks wider than 1 inch. |

|

|

3 Crack seal – Sand slurry seal should only be used if there is an overlay scheduled within 1 year or less of the maintenance work. 4 Rutting refers to when the pavement is unstable and pushing or shoving. It is best to remove rutting/shoving pavement. 5 Studded tire wear refers to the distinct wear in the wheelpaths caused by studded tires. The best techniques to deal with this distress are to fill in with a wheelpath chip seal or remove the issue. 6 Raveling – Fog seal will work best for low-severity raveling. 7 If placing a grader patch or thin overlay in locations of rutting or studded tire wear, ensure the use of a pneumatic roller to achieve compaction. In general, the best choices will yield the longest service lives. |

It identifies two instances where mastics are the best repair material (transverse and longitudinal cracks more than 1 inch wide), and no other treatment is identified as an alternate. Chapter 3 in WSDOT’s Maintenance Manual links different pavement conditions to suitable repairs (WSDOT 2020). Mastics are mentioned for transverse cracks, but not for longitudinal cracks. Mastic sealing is not identified as a sealing strategy in the portion of Chapter 3 dedicated to treatment descriptions.

Performance

While WSDOT has used mastics for longer than many other DOTs, they do not have good performance data for this treatment. They have observed that many factors affect performance, focusing on the condition of the pavement, the depth and width of the cracks, the quality of the placement, and traffic levels. Treatment life varies; the standard expected life is 4 years, but it can be 5 years or more on lower-volume roads. When the pavement has deteriorated to the point that wide crack sealing no longer works, the next most cost-effective treatment is a 1.8-inch mill and fill. If the pavement surface is in acceptable condition, however, the next treatment would be a chip seal. In some cases, it is the surrounding pavement that is failing faster than the sealant material. A general observation is that pavements with wide cracks requiring repair are often

near the end of their service lives. Using mastics provides a couple of extra years until rehabilitation is needed. Eventually, pavements reach a point where the life-extending benefit does not meet a minimum threshold to warrant the use of sealing treatments.

Innovations

WSDOT’s most recent innovation is using mastics for repairs on spalled concrete joints, especially on the west side of the state. It has been successful and can be placed quicker and at a lower cost than conventional concrete spall patching. The practice is spreading to other WSDOT regions.

Experience Gained

WSDOT has learned several lessons about when mastics are applicable and how they can be used. For example, in early applications mastic crack sealing operations would most typically be followed immediately by a chip seal; now they extend treatment service life for at least one year prior to construction of a follow-up chip seal. WSDOT has also learned that the most problematic cracks to seal are deep cracks, not wide cracks. WSDOT has used mastics over centerline longitudinal joints which include recessed pavement markers but has learned that mastics are not appropriate over opened centerline longitudinal joints with rumble strips. In those instances, a 3-feet wide mill and replace is the preferred repair method.

Challenges Identified by WSDOT

WSDOT identified several challenges related to the use of mastics:

- Proper equipment operation can be challenging for several reasons. It requires maintaining a uniformly high temperature for placement and adding cold material to the heater/applicator affects that requirement. The vendor’s recommendations should be followed carefully for proper equipment operation.

- WSDOT has observed the importance of proper crack cleaning. If the crack is not clean, the mastic will not bond well and can fail prematurely.

- They have experienced more problems sealing deep cracks rather than wide cracks. In addition to the difficulties in cleaning a deep crack, the material in such cracks can sag, leaving a slight depression rather than a flush surface.

Opportunities

WSDOT identified several opportunities related to the use of mastics:

- WSDOT recognized that mastics applied to wide cracks provide additional service life. Determining appropriate remaining life extensions based on different pavement conditions would improve the modeling capabilities of their pavement management system.

- Mastics are identified as a work operation in WSDOT’s MMS. However, it is given the same work code as rubberized crack sealing, slurry seal crack sealing, and crack/joint sealing in concrete pavements, so it is not possible to monitor the use and performance of each as a unique activity. Introducing separate work codes would improve WSDOT’s ability to analyze performance.

- Better documentation about mastic use, such as in WSDOT’s Maintenance Manual, would help in material and project selection.

- WSDOT does not have a training module for mastic applications and would like to add such training to those already existing for pavement preservation actions.

- WSDOT specifications for mastic sealants refer to the ASTM specification. This could be further customized to include additional preparation and application best practices, identifying conditions appropriately maintained with mastic seals, and providing guidance on materials appropriate for WSDOT’s different regions.

- While WSDOT has observed differential performance based on traffic levels, there is no guidance on use based on traffic. There is an opportunity to develop and communicate such guidance.