Material Requirements for High-Tension Cable Barriers: A Guide (2025)

Chapter: Appendix C: Survey of States Responses

APPENDIX C

Survey of States Responses

As part of the literature review, the research team reviewed the survey questionnaires from both NCHRP Synthesis 493 and NCHRP Report 711. Overall, these surveys were aimed at collecting information from states on their use, selection, and placement criteria for high-tension cable barriers. Although this project will benefit from the information collected and synthesized in the previous studies, the objective of this project is more concerned with material properties, material testing, and coating requirements; thus, a survey that addressed material properties and states standard specifications/details/provisions was developed. The content of the survey that was distributed to the states included

- Twenty-five from NCHRP Synthesis 493. In some cases, it was necessary to edit the questions to add new information, or to improve comprehension;

- Five questions from NCHRP Report 711; and

- Eleven new questions that were designed to cover new content and were aimed at collecting material property, testing, and coating information.

A distribution list for the survey was assembled and included contacts from each of the 50 states. The survey was built using the online program SurveyMonkey, and the survey was opened for responses on October 21, 2022. Analysis of survey responses began on November 28, 2022; however, the survey link was not closed, to allow additional responses. The survey, as published on the SurveyMonkey site, can be found in Appendix B.

This analysis of the survey is a supplement to the State DOT Specifications and State DOT Practices chapters of the literature review, sections 2.3 and 2.4, respectively.

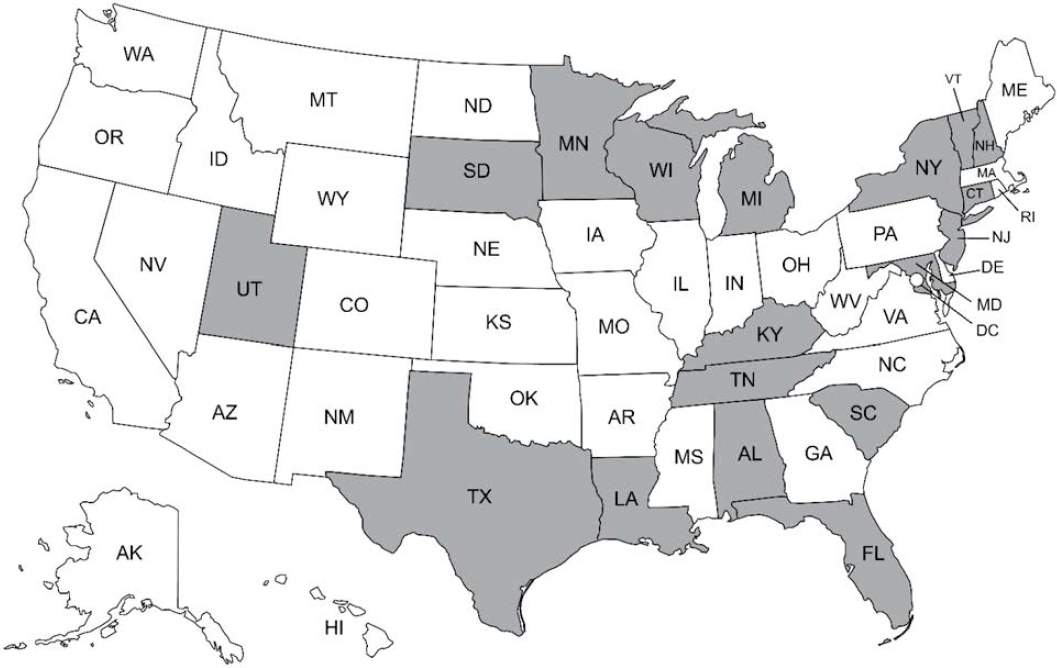

Contact Information and Agency of Respondents

The first set of questions in the state-of-practice HTCB survey offered respondents the opportunity to provide contact information and agency information. Nineteen respondents initiated the survey and completed Question 1. The 19 respondents represented 17 agencies; Michigan DOT and Minnesota DOT were represented by multiple respondents. One additional state, Connecticut, responded to the survey by directly emailing the research team. A map indicating the states that responded is shown as Figure C-1.

Types of Cable Barrier

Question 2 asked respondents what cable barrier types are currently being installed on the roadside or median by their agency. Seventeen of the respondents provided responses to this question. The answers provided can be seen in Figures C-2 and C-3 and in Table C-1. Of the

Table C-1. Tabulation of survey responses for Question 2.

| Answer Choices | Responses | |

|---|---|---|

| None of the above | 20% | 4 |

| Low Tension | 15% | 3 |

| High Tension | 65% | 13 |

17 states that responded, five were subsequently excluded from the survey analysis for the following reasons:

- Connecticut, New Jersey, and New Hampshire responded that they do not use cable barrier. The remainder of responses from these states were therefore omitted from the survey analysis.

- Vermont responded that their use of HTCB was limited to a pilot program that resulted in challenges with post replacement in inclement weather and that further use of HTCB has not been implemented. Since Vermont’s experience was limited to a pilot program, their responses were also excluded from the survey analysis.

- Alabama responded to Question 1 of the survey but provided no other responses to survey questions. Alabama’s responses were removed from the survey analysis; however, they are included in the review of State DOT Specifications and Special Provisions chapter of the literature review.

Types of HTCB

Question 3 asked respondents what HTCB-specific designs are approved/qualified for use by their agency. Thirteen participants responded to this question, and their responses are shown in Table C-2 and Figure C-4. Note that multiple responses were allowed to this question. Louisiana reported that they do not have an approved products list but that the cable barrier systems used in their state must be high-tension, 4-cable systems that meet MASH requirements and have an FHWA eligibility letter.

Table C-2. Tabulation of survey responses for Question 3.

| Answer Choices | Responses | |

|---|---|---|

| None of the above | 15% | 2 |

| Brifen – Wire Rope Safety Fence (WRSF) | 85% | 11 |

| Valtir – CASS® | 46% | 6 |

| Valtir – NU-CABLE™ | 15% | 2 |

| Gregory Highway Products – SAFENCE® | 8% | 1 |

| Nucor Steel Marion – Cable Barrier System | 15% | 2 |

| Gibraltar – NCHRP Report 350 Cable Barrier System | 46% | 6 |

| Gibraltar – MASH16 Cable Barrier System | 23% | 3 |

| Other (please specify) | 8% | 1 |

Types of HTCB Terminals

Question 4 asked respondents what HTCB terminal designs are approved/qualified for use by their agency. Thirteen participants responded to this question, and their responses are shown in Table C-3 and Figure C-5. Multiple responses were allowed for this question. Again, Louisiana reported that they do not have an approved products list, but they require that systems used in their state must be 4-cable, high-tension MASH systems with an FHWA eligibility letter. Similarly, Minnesota requires that systems installed in their state have an eligibility letter from the FHWA and that the system meets or exceeds either MASH TL-3 or NCHRP Report 350 TL-3 requirements.

State Specifications for HTCB

Question 5 asked respondents if their agency has developed specifications for HTCB. Twelve participants responded to this question, and their responses are shown in Table C-4 and Figure C-6. Of the 12 respondents, two states indicated that their agency has developed specifications for each eligible system, four states have developed specifications but are not product specific, three states use manufacturer specifications, and three indicated that they have no specifications.

Table C-3. Tabulation of survey responses for Question 4.

| Answer Choices | Responses | |

|---|---|---|

| None of the above | 31% | 4 |

| Brifen – MASH Terminal | 38% | 5 |

| Brifen – Wire Rope Gating Terminal (WRGT) System | 46% | 6 |

| Gregory Highway Products – High-Tension 3-Cable SAFENCE End Terminal | 8% | 1 |

| Gibraltar – TL-3 4-Cable End Terminal | 54% | 7 |

| Trinity CASS Cable Terminal | 23% | 3 |

| Other (please specify) | 23% | 3 |

Table C-4. Tabulation of survey responses for Question 5.

| Answer Choices | Responses | |

|---|---|---|

| Yes, specifications have been developed for each eligible system. | 17% | 2 |

| Yes, specifications have been developed but are not product specific. | 33% | 4 |

| No, use manufacturers specifications. | 25% | 3 |

| No. | 25% | 3 |

Questions 6 through 9 of the survey provided an opportunity for respondents to upload or provide links to their agency’s HTCB standard specifications and HTCB Standard Drawings. Six respondents provided access to standard specifications, and six respondents provided access to standard drawings.

Special Provisions for HTCB

Question 10 asked respondents if their agency has developed HTCB Special Provisions. Twelve participants responded to this question, and their responses are shown in Table C-5 and Figure C-7. Of the twelve respondents, five states have not developed special provisions for HTCB, five states have universal provisions that apply to any/all HTCB designs, one state develops special provisions on a project-by-project basis, and New York responded that they use standard anchor blocks that are designed based on the tension loads for each specific system.

Questions 11 and 12 of the survey provided an opportunity for respondents to upload or provide links to their agency’s HTCB special provisions. Five respondents provided access to their agency’s special provisions.

Material Specifications

Question 13 asked respondents if any material specifications for HTCB components are defined by their agency. Twelve participants responded to this question, and their responses are shown in Table C-6 and Figure C-8. Half of the respondents indicated that no material specifications were

Table C-5. Tabulation of survey responses for Question 10.

| Answer Choices | Responses | |

|---|---|---|

| No. | 42% | 5 |

| Yes, universal – apply to any/all HTCB designs. | 42% | 5 |

| Yes, project-by-project basis. | 8% | 1 |

| Yes, project specific. | 0% | 0 |

| Other (please specify) | 8% | 1 |

defined by their agency, and the other six agencies did have material specifications defined. All the respondents who answered “Yes” pointed the research team back to their standard specifications, details, or special provisions.

Table C-6. Tabulation of survey responses for Question 13.

| Answer Choices | Responses | |

|---|---|---|

| No | 50% | 6 |

| Yes (please describe) |

50% | 6 |

Material Testing

Question 14 asked respondents if components used in HTCB are tested to confirm their material properties before installation. Twelve participants responded to this question, and their responses are shown in Table C-7 and Figure C-9. Note that multiple responses were allowed to this question. Of the 12 respondents, one agency performs testing on a random sample of components, eight agencies require the contractor/manufacturer to perform material testing and provide certificates of compliance, and four agencies do not require testing or certification.

Table C-7. Tabulation of survey responses for Question 14.

| Answer Choices | Responses | |

|---|---|---|

| Yes, the agency performs materials testing on a random sample of components. | 8% | 1 |

| Yes, the agency requires the contractor/manufacturer to perform materials testing and provide certificates of compliance. | 67% | 8 |

| No materials testing or certification is required. | 33% | 4 |

Material Testing – Specific Components

Question 15 asked respondents which HTCB system components are tested by their agency. Four participants responded to this question, and their responses are shown in Table C-8.

Material Testing - By Contractor/Supplier

Question 16 asked respondents which HTCB components are tested by the contractor or manufacturer. Six participants responded to this question, and their responses are shown in Table C-9.

Table C-8. Responses to Question 15.

| Respondent | Response Text |

|---|---|

| WI | Concrete material requires testing. Steel reinforcement may be sampled and tested. Galvanization of steel may be tested. |

| TX | Hydraulic cement concrete. |

| MN | The majority of the time we do not test. There are a few rare occasions where components (cable, coating, steel, etc.) are tested. |

| UT | All except for concrete for foundations. |

Table C-9. Responses to Question 16.

| Respondent | Response Text |

|---|---|

| WI | Contractor/supplier should be providing material certifications for steel and galvanization. |

| MD | Cable tension testing. |

| FL | Cable and fittings. |

| UT | The Department tests concrete used for foundations. Mix design, air, slump, strength. |

| MI | Cables and fittings. |

| LA | The wire rope requires a certificate of compliance. The tension testing device requires a calibration certificate. |

Pull Testing of Cable and Fittings

Question 17 asked respondents if their agency requires pull testing of fully fitted splices to determine breaking strength. Eleven participants responded to this question, and their responses are shown in Table C-10 and Figure C-10. Of the 11 respondents, two states require pull testing to determine the breaking strength of the splice and nine states do not.

Table C-10. Tabulation of survey responses for Question 17.

| Answer Choices | Responses | |

|---|---|---|

| Yes | 18% | 2 |

| No | 82% | 9 |

Pre-Stretched Cable

Question 18 asked respondents if pre-stretching of the HTCB wire rope is required by their agency. Eleven participants responded to this question, and their responses are shown in Table C-11 and Figure C-11. Of the eleven respondents, seven states require pre-stretching of the cables and four states do not.

Table C-11. Tabulation of survey responses for Question 18.

| Answer Choices | Responses | |

|---|---|---|

| Yes | 64% | 7 |

| No | 36% | 4 |

Table C-12. Responses to Question 19.

| Respondent | Response Text |

|---|---|

| WI | Cable strength of 39 kips. Note that splices are required to be of equal strength of the cable barrier. |

| LA | 0.5 * Tensile Strength |

| UT | Materials must meet manufacturers’ requirements. |

| MN | Yes |

| MI | 50% (minimum) of cable’s tensile strength. |

Pre-Stretching Load Requirements

Question 19 asked respondents to specify their agency’s pre-stretching load requirement. Five participants responded to this question, and their responses are shown in Table C-12.

Median Versus Roadside Installations

Question 20 asked respondents where cable barrier systems are installed by their agency. Eleven participants responded to this question, and their responses are shown in Table C-13 and Figure C-12. Note that multiple responses were allowed to this question. All 11 respondents indicated that their agency uses HTCB in medians and seven of those also use HTCB in roadside applications.

Table C-13. Tabulation of survey responses for Question 20.

| Answer Choices | Responses | |

|---|---|---|

| Median | 100% | 11 |

| Roadside | 64% | 7 |

| None | 0% | 0 |

Number of Cables

Question 21 asked respondents if their agency specifies the minimum number of cables used. Eleven participants responded to this question, and their responses are shown in Table C-14 and Figure C-13. Of the 11 respondents, two agencies do not specify a minimum number of cables, two agencies specify a minimum of 3 cables, and seven agencies specify a minimum of 4 cables.

Table C-14. Tabulation of survey responses for Question 21.

| Answer Choices | Responses | |

|---|---|---|

| No | 18% | 2 |

| Yes, 3 cables | 18% | 2 |

| Yes, 4 cables | 64% | 7 |

Minimum Test Level

Question 22 asked respondents if their agency specifies the minimum system Test Level for HTCB systems installed in their state. Eleven participants responded to this question, and their responses are shown in Table C-15 and Figure C-14. Of the 11 respondents, two indicated that their agencies do not specify a minimum test level for HTCB, seven agencies specify a minimum of TL-3, and two agencies specify a minimum of TL-4 for HTCB.

Table C-15. Tabulation of survey responses for Question 22.

| Answer Choices | Responses | |

|---|---|---|

| No | 18% | 2 |

| Yes, Test Level 3 | 64% | 7 |

| Yes, Test Level 4 | 18% | 2 |

Barrier Warrants

Question 23 asked respondents how their agency decides when HTCB or other barrier types are warranted in a highway median or roadside. Eleven participants responded to this question, and their responses are shown in Table C-16 and Figure C-15. Note that multiple responses were allowed to this question. Utah, which was the only state to select “other” as their answer, responded that designers can choose to install barrier systems based on financial considerations, repair costs, median width, and sometimes average daily traffic.

Site Design

Question 24 asked respondents what the site design for a specific HTCB project is based on. Eleven participants responded to this question, and their responses are shown in Table C-17 and Figure C-16. Of the 11 respondents, three indicated that their agencies base the site design on

Table C-16. Tabulation of survey responses for Question 23.

| Answer Choices | Responses | |

|---|---|---|

| Use AASHTO Roadside Design Guide (RDG) warrants. | 45% | 5 |

| Use agency-developed warrants. | 64% | 7 |

| Crash history. | 64% | 7 |

| Other (please specify) | 9% | 1 |

| None of the above | 0% | 0 |

Table C-17. Tabulation of survey responses for Question 24.

| Answer Choices | Responses | |

|---|---|---|

| A specific HTCB system. | 27% | 3 |

| Designed independent of the system ultimately used. | 73% | 8 |

a specific HTCB system, and eight agencies use a site design that is independent of the system ultimately used.

Anchor Foundation Design

Question 25 asked respondents if HTCB anchor foundations are designed on a project-by-project basis according to the site-specific soil type/conditions. Eleven participants responded to this question, and their responses are shown in Table C-18 and Figure C-17. Of the 11 respondents, seven indicated that the designs are done by the HTCB manufacturer, and four indicated

Table C-18. Tabulation of survey responses for Question 25.

| Answer Choices | Responses | |

|---|---|---|

| Yes, designs are done by agency. | 0% | 0 |

| Yes, designs are done by HTCB manufacturer of the system being installed. | 64% | 7 |

| No, a standard design is used. | 36% | 4 |

that their agency uses a standard design. Questions 26 and 27 of the survey provided an opportunity for respondents to upload or provide links of example anchor foundation designs. One respondent provided access to their design.

Anchor Foundation Placement and Spacing

Question 28 asked respondents how their agency determines the placement and spacing of HTCB anchor foundations. Ten participants responded to this question, and their responses are shown in Tables C-19 and C-20 and Figure C-18. Of the 10 respondents, four indicated that placement of anchor foundations is done by their agency based on state specifications, one indicated that the placement is determined by the HTCB manufacturer, and five of the respondents answered “other.” Their responses are provided in Table C-20.

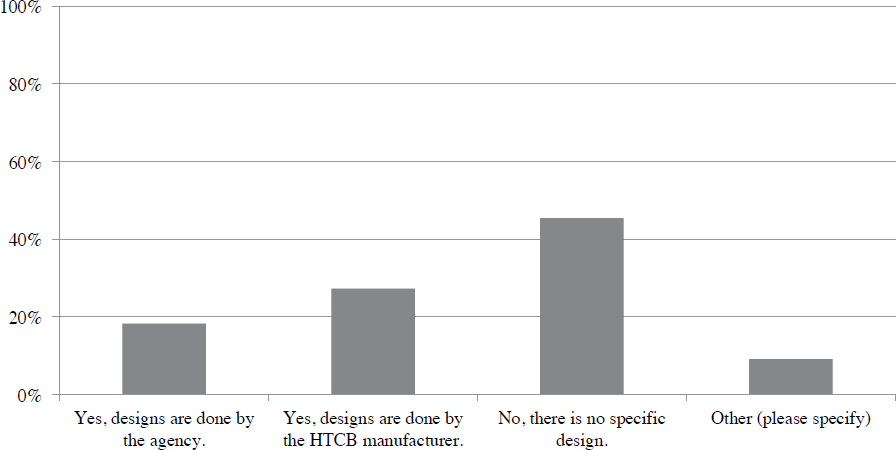

Concrete Line Post Footing Design

Question 29 asked respondents if concrete line post footers are designated on a project-by-project basis based on the site-specific soil type/condition. Eleven participants responded to this question, and their responses are shown in Table C-21 and Figure C-19. Of the 11 respondents, two indicated that the line post footers are designed by the agency, five respondents indicated that the design is done by the HTCB manufacturer, three responded that no specific design is used,

Table C-19. Tabulation of survey responses for Question 28.

| Answer Choices | Responses | |

|---|---|---|

| Done by agency based on the state’s specifications. | 36% | 4 |

| Done by the HTCB manufacturer of the system being installed. | 9% | 1 |

| Other (please specify) | 45% | 5 |

Table C-20. Responses for answer choice: “Other (please specify)” Question 28.

| Respondent | Response Text |

|---|---|

| WI | Most of the time, the geometry of the roadway causes a break in the barrier. A bridge or median opening will cause a break in the cable barrier. |

| SD | Designed for each project. |

| UT | Brifen does not have a maximum barrier length before placement of the MASH Gating Terminal. Currently, Utah has barrier runs up to 9 miles in length from one terminal to another. |

| MN | 4 feet from the P.I. or less if there is a site limitation. |

| LA | The lengths of cable barrier vary by project and are typically shown in the plans but are not based on a standard specification. |

Table C-21. Tabulation of survey responses for Question 29.

| Answer Choices | Responses | |

|---|---|---|

| Yes, designs are done by the agency. | 18% | 2 |

| Yes, designs are done by the HTCB manufacturer. | 45% | 5 |

| No, there is no specific design. | 27% | 3 |

| Socketed posts are not used. | 9% | 1 |

and one indicated that socketed posts are not used. Questions 30 and 31 of the survey provided an opportunity for respondents to upload or provide links of an example concrete line post footing design. Two respondents provided access to an example concrete line post footing design.

Mow Strip Use

Question 32 asked respondents if mow strips are used at the respondent’s agency. Eleven participants responded to this question, and their responses are shown in Table C-22 and Figure C-20. Of the 11 respondents, three indicated that mow strips are used on all HTCB projects, one indicated that they are sometimes used on a project-by-project basis, and seven indicated that mow strips are not used by their agency.

Mow Strip Material

Question 33 asked respondents what material mow strips constructed of, if they are used. Four participants responded to this question, and their responses are shown in Table C-23.

Table C-22. Tabulation of survey responses for Question 32.

| Answer Choices | Responses | |

|---|---|---|

| Yes, mow strips are used on all HTCB projects. | 27% | 3 |

| Sometimes, mow strips are used on a project-by-project basis. | 9% | 1 |

| No, mow strips are not used. | 64% | 7 |

Table C-23. Responses to Question 33.

| Respondent | Response Text |

|---|---|

| FL | Asphalt and concrete are options. |

| UT | We had mow strips in standards from 2012 to 2017. 100 percent of the projects asked for a deviation from standards and did not install a mow strip. So, we removed the requirement. |

| SC | Asphalt is most common, but concrete is also allowed. |

| LA | Reinforced concrete. |

Design Modifications for Curves

Question 34 asked respondents if there is any design modification (post spacing) for horizontal or vertical curves. Eleven participants responded to this question, and their responses are shown in Table C-24 and Figure C-21. Of the 11 respondents, two indicated that the post spacing designs on horizontal and vertical curves are done by the state agency, three indicated that the designs are done by the HTCB manufacturer, and five indicated that their agency has no specific post spacing design for curves. NYDOT responded that they require 10-foot post spacing and do not allow installation of cable barriers on curves with a radius of less than 500 feet. Questions 35 through 38 of the survey provided an opportunity for respondents to upload or provide links to an example HTCB design for horizontal curves and vertical curves. None of the respondents provided access to an example HTCB design for horizontal curves and vertical curves.

HTCB to Other Barrier Transitions

Question 39 asked respondents how they address the interface/overlap of HTCB with a metal beam or concrete barrier. Ten participants responded to this question, and their responses are shown in Table C-25.

Design-Related HTCB Issues

Question 40 asked respondents if there are any design-related HTCB issues that they believe need to be addressed by additional research. Seven participants responded to this question, and their responses are shown in Table C-26. Questions 41 and 42 of the survey provided an

Table C-24. Tabulation of survey responses for Question 34.

| Answer Choices | Responses | |

|---|---|---|

| Yes, designs are done by the agency. | 18% | 2 |

| Yes, designs are done by the HTCB manufacturer. | 27% | 3 |

| No, there is no specific design. | 45% | 5 |

| Other (please specify) | 9% | 1 |

Table C-25. Responses to Question 39.

| Respondent | Response Text |

|---|---|

| WI | We try to have the cable barrier go behind the other barrier system. We try to lap the LON points of the two systems so vehicles cannot gate through. |

| MD | MDOT SHA Guidelines for Traffic Barrier Placement and End Treatment Design recommend overlapping the cable barrier and w-beam with the w-beam running behind the cable barrier with a minimum 10-foot offset. |

| SD | We consider them to be two independent systems and would either utilize an overlap or gap so there is no interaction between the two systems. |

| FL | Overlap and provide sufficient offset between barrier for deflection. |

| MN | The different scenarios for overlap for beam guardrail is shown in our standard plan. For concrete we generally lap the HTCB in front of the concrete barrier and most of the time the concrete barrier will have a crash cushion as well. The spacing between the HTCB and the crash cushion is large enough there isn’t interaction between the two. |

| UT | See the BA 5 Series Standard Drawings. |

| NY | Have not accommodated the interface. |

| MN | See tech memo. |

| MI | The two are overlapped a certain distance. |

| LA | Connections to other barriers are made based on the manufacturer’s recommendations provided such connections have been crash tested and accepted by FHWA. Typically, we overlap the two barrier systems by approx. 50'-0". |

Table C-26. Responses to Question 40.

| Respondent | Response Text |

|---|---|

| WI | How much movement of cable barrier terminals is acceptable? How much damage should a line post footing or end anchor footing is acceptable? Is the cable height tolerance listed in NCHRP report 711 (1") reasonable? |

| SD | Yes. We need a MASH approved HTCB to steel beam transition. |

| MN | We get the most questions about the anchor foundation. I believe folks are looking for additional or clarification on guidance. |

| UT | A w-beam to HTCB transition needs to be developed. This system would allow for a continuous barrier face from HTCB to w-beam then to concrete barrier. Utah has been working with Pooled funds during the problem statement submissions process. So far not enough states vote to move forward. Will continue to try. |

| MN | Cost |

| MI | None that come to mind. |

| LA | Most cable barriers are tested on a flat surface or on a 1V:4H slope. However, there has been some confusion as to what constitutes a “flat” surface. Is 1V:10H flat? Is greater than 1V:6H flat? Also, a system that could be installed on a 1V:3H slope would be beneficial as well. |

opportunity for respondents to upload or provide links of typical design-related HTCB concerns. Utah Department of Transportation provided a photo of a typical design-related HTCB concern, shown in Figure C-22.

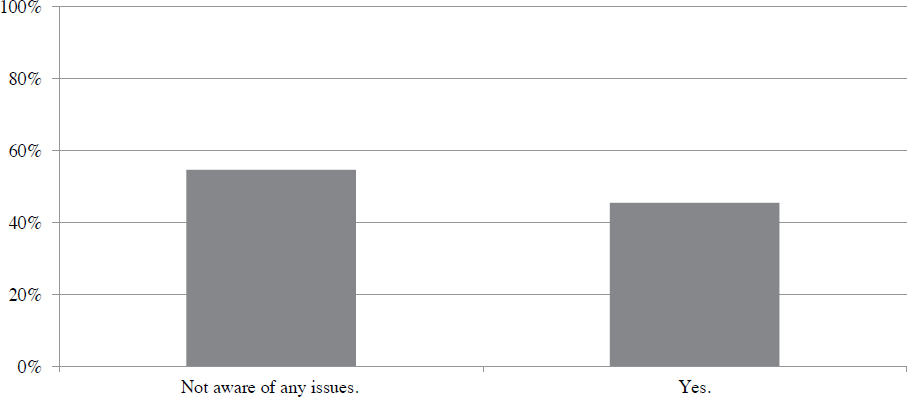

HTCB Challenges

Question 43 asked respondents if their agency experienced any challenges related to HTCB installation. Eleven participants responded to this question, and their responses are shown in Table C-27 and Figure C-23. Of the 11 respondents, six were not aware of any issues related to HTCB installations. Five participants followed up with a discussion of those challenges in the responses to Question 44. The responses are shown in Table C-28. Questions 45 and 46 of the survey provided an opportunity for respondents to upload or provide links of typical installation-related HTCB concerns. None of the respondents provided links or photos to their specific HTCB installation concerns.

Table C-27. Tabulation of survey responses for Question 43.

| Answer Choices | Responses | |

|---|---|---|

| Not aware of any issues. | 55% | 6 |

| Yes. | 45% | 5 |

Table C-28. Responses to Question 44.

| Respondent | Response Text |

|---|---|

| WI | Poor/wet soils; poor workmanship; poor line-post performance; inadequate reinforcement; footing movement. |

| MN | Lack of training for proper installation with each product. |

| UT | Cable barrier placed near ditch bottom with saturated soils causing the foundation to roll out of the ground during impact. Moving the line posts 1.5 feet from ditch bottom and required a 42-inch-deep concrete foundation has cured the problem. Also found that if the barrier is placed closer than 8 feet from the edge of travel lane then nuisance impacts become such a problem that the run was relocated within a year of installation. Also found that if the barrier is placed more than 15 feet from edge of travel lane then a large percent of errant vehicles started a rolling motion and traversing over the barrier, we have found if placed 15 feet from edge of travel lane then the vehicle is captured before a rolling motion occurs. |

| MN | Cost. |

| LA | On a recent project the contractor had issues setting the sockets correctly and keeping the line posts plumb. |

Table C-29. Tabulation of survey responses for Question 47.

| Answer Choices | Responses | |

|---|---|---|

| Provided by installation contractor as part of installation bid package. | 0% | 0 |

| Acquired by the maintenance contractor. | 60% | 6 |

| Acquired direct from the manufacturer. | 30% | 3 |

| Other (please specify) | 10% | 1 |

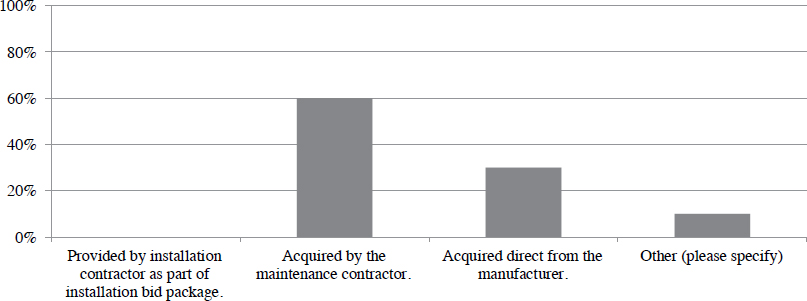

Repair Material Requisition

Question 47 asked respondents how materials that are required for repair of the HTCB systems (e.g., wire rope, posts, turnbuckles, fittings, etc.) are acquired by their agency. Ten participants responded to this question, and their responses are shown in Table C-29 and Figure C-24. Of the 10 respondents, six indicated that repair material was acquired by the maintenance contractor, and three indicated that repair material was acquired directly from the manufacturer. Wisconsin selected “Other” and indicated that the state forces the purchase of hardware.

Quantity of Repair Materials

Question 48 asked respondents in the case that repair materials are provided by the installation contractor as part of the installation bid package, please describe how much repair materials are provided (e.g., a percentage of installation length, standard quantity for each piece, quantity as a function of system length, etc.). Since repair materials are not supplied by the installation contractor as part of the bid package (see Question 47), there were no responses provided for this question.

Table C-30. Tabulation of survey responses for Question 49.

| Answer Choices | Responses | |

|---|---|---|

| Yes | 10% | 1 |

| No | 80% | 8 |

| Other (please specify) | 10% | 1 |

Rusting and Oxidation

Question 49 asked respondents if their agency has noted concerns with rusting or oxidation of galvanized components of HTCB systems. Ten participants responded to this question, and their responses are shown in Table C-30 and Figure C-25. Of the 10 respondents, one indicated that rusting was an issue, and eight indicated that rusting was not an issue. New York reported that in isolated cases the socketed posts have corroded badly in the sockets.

Cable Tension Check Frequency

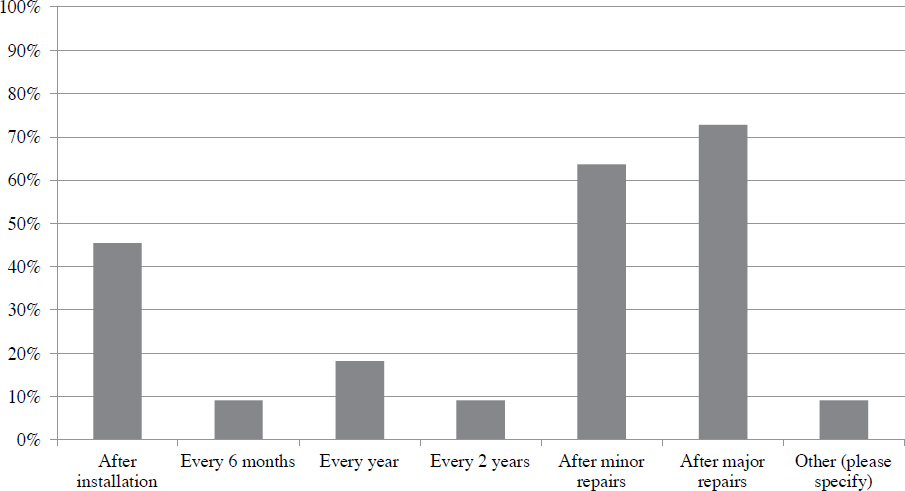

Question 50 asked respondents how frequently the cable tension is checked. Eleven participants responded to this question, and their responses are shown in Table C-31 and Figure C-26. Note that multiple selections could be made for this question. Maryland reported that the frequency at which repairs are made to their HTCB systems allows tension to be regularly checked.

Table C-31. Tabulation of survey responses for Question 50.

| Answer Choices | Responses | |

|---|---|---|

| After installation | 45% | 5 |

| Every 6 months | 9% | 1 |

| Every year | 18% | 2 |

| Every 2 years | 9% | 1 |

| After minor repairs | 64% | 7 |

| After major repairs | 73% | 8 |

| Other (please specify) | 9% | 1 |

Anchor Foundation Movement Monitoring

Question 51 asked respondents if the in-service movement of anchor foundations is monitored. Eleven participants responded to this question, and their responses are shown in Table C-32 and Figure C-27. One of the respondents indicated that anchor movement was monitored only once after installation, two indicated that anchor movement was monitored after installation and then periodically thereafter, and eight indicated that anchor movement is never monitored.

Table C-32. Tabulation of survey responses for Question 51.

| Answer Choices | Responses | |

|---|---|---|

| Yes, after installation only. | 9% | 1 |

| Yes, after installation and periodically thereafter. | 18% | 2 |

| No. | 73% | 8 |

HTCB Failure Modes

Question 52 asked respondents to indicate if the following cable barrier failure modes have occurred to the HTCB installed by their agency. Ten participants responded to this question, and their responses are shown in Tables C-33 and C-34 and Figure C-28. Note that multiple selections were allowed for this question. The highest percentage of barrier failures were related to soil conditions at either end-anchors or post footers. However, Utah responded that changes within their standards have resolved most of the issues related to soil conditions around anchors.

Used Parts for Repairs

Question 53 asked respondents if their agency utilizes used parts in repairs and, if so, has it caused problems. Eleven participants responded to this question, and their responses are shown in Table C-35 and Figure C-29. Of the 11 respondents, one indicated that they have had problems

Table C-33. Tabulation of survey responses for Question 52.

| Answer Choices | Responses | |

|---|---|---|

| None of the above | 9% | 1 |

| Cable failure during impact. | 9% | 1 |

| Failure at end of cable connections. | 18% | 2 |

| Failure at connection between cables and end anchors. | 0% | 0 |

| Excess barrier deflection during impact due to horizontal curvature. | 9% | 1 |

| Excess barrier deflection due to long anchor-to-anchor segments. | 9% | 1 |

| Penetrations/excess deflection due to long post spacing. | 9% | 1 |

| Penetration/excess deflection due to cable spacing or number of cables. | 9% | 1 |

| End-anchor pull-out due to soil condition. | 45% | 5 |

| End-anchor failure due to concrete failure. | 9% | 1 |

| Post footer pull-out due to soil condition. | 45% | 5 |

| Post footer failure due to post sleeve concrete failure. | 27% | 3 |

| Other (please specify) | 27% | 3 |

Table C-34. Responses for answer choice: “Other (please specify)” Question 52.

| Respondent | Response Text |

|---|---|

| WI | Poor workmanship; not following provided details. |

| LA | Many of our HTCB’s are installed on slope and we have had issues with under-rides. Also, there have been instances where vehicles have hit the end anchor directly and caused the cables to detach. |

| UT | Answers provided here (end-anchor pull-out, and foundation pull-out due to soil conditions) are with regards to the NCHRP-350 systems from 2009 to 2012. Changes within our standards have resolved most of the issues. |

Table C-35. Tabulation of survey responses for Question 53.

| Answer Choices | Responses | |

|---|---|---|

| Yes, some problems. | 9% | 1 |

| Yes, no problems. | 18% | 2 |

| No, used parts are not used in repairs. | 73% | 8 |

using used parts, two indicated that they have installed used parts with no issues, and eight respondents indicated that their agency has not installed used parts in repairs.

Table C-36. Tabulation of survey responses for Question 54.

| Answer Choices | Responses | |

|---|---|---|

| Yes | 18% | 2 |

| No | 82% | 9 |

HTCB In-Service Performance Evaluations

Question 54 asked respondents if their agency performed an in-service performance evaluation on any HTCB installations. Eleven participants responded to this question, and their responses are shown in Table C-36 and Figure C-30. Of the respondents, only two, Wisconsin and Florida, indicated that their agency had performed an ISPE on HTCB systems. Questions 55 and 56 of the survey provided an opportunity for respondents to upload or provide links to an ISPE report. One respondent provided access to an ISPE report.

Abbreviations and acronyms used without definitions in TRB publications:

| A4A | Airlines for America |

| AAAE | American Association of Airport Executives |

| AASHO | American Association of State Highway Officials |

| AASHTO | American Association of State Highway and Transportation Officials |

| ACI–NA | Airports Council International–North America |

| ACRP | Airport Cooperative Research Program |

| ADA | Americans with Disabilities Act |

| APTA | American Public Transportation Association |

| ASCE | American Society of Civil Engineers |

| ASME | American Society of Mechanical Engineers |

| ASTM | American Society for Testing and Materials |

| ATA | American Trucking Associations |

| CTAA | Community Transportation Association of America |

| CTBSSP | Commercial Truck and Bus Safety Synthesis Program |

| DHS | Department of Homeland Security |

| DOE | Department of Energy |

| EPA | Environmental Protection Agency |

| FAA | Federal Aviation Administration |

| FAST | Fixing America’s Surface Transportation Act (2015) |

| FHWA | Federal Highway Administration |

| FMCSA | Federal Motor Carrier Safety Administration |

| FRA | Federal Railroad Administration |

| FTA | Federal Transit Administration |

| GHSA | Governors Highway Safety Association |

| HMCRP | Hazardous Materials Cooperative Research Program |

| IEEE | Institute of Electrical and Electronics Engineers |

| ISTEA | Intermodal Surface Transportation Efficiency Act of 1991 |

| ITE | Institute of Transportation Engineers |

| MAP-21 | Moving Ahead for Progress in the 21st Century Act (2012) |

| NASA | National Aeronautics and Space Administration |

| NASAO | National Association of State Aviation Officials |

| NCFRP | National Cooperative Freight Research Program |

| NCHRP | National Cooperative Highway Research Program |

| NHTSA | National Highway Traffic Safety Administration |

| NTSB | National Transportation Safety Board |

| PHMSA | Pipeline and Hazardous Materials Safety Administration |

| RITA | Research and Innovative Technology Administration |

| SAE | Society of Automotive Engineers |

| SAFETEA-LU | Safe, Accountable, Flexible, Efficient Transportation Equity Act: A Legacy for Users (2005) |

| TCRP | Transit Cooperative Research Program |

| TEA-21 | Transportation Equity Act for the 21st Century (1998) |

| TRB | Transportation Research Board |

| TSA | Transportation Security Administration |

| U.S. DOT | United States Department of Transportation |